Are you are finding that your inkjet printer ink is being used up quicker than you like? There is valid explanation for this. The ink is going down the drain, literarily. This is not neccessarily a bad thing however. Read on to learn how the ink in your printer is used in your inkjet printer.

Are you are finding that your inkjet printer ink is being used up quicker than you like? There is valid explanation for this. The ink is going down the drain, literarily. This is not neccessarily a bad thing however. Read on to learn how the ink in your printer is used in your inkjet printer.

In most inkjet/bubble jet printers there is a device called the ink absorber pad. The size and implementation of this varies between manufacturers and makes but its purpose remains the same. The ink absorber pad is designed to collect any wasted ink that is expelled by the printing head when the printer performs its cleaning cycle.

Wasted ink does not indicate a fault of the printer but is part of normal operation; however when the various ink absorption pads in a printer may fill up the printer may indicate this as an error and printing will not be possible unless the pad is changed and the error cleared.

This type of error is extremely common with printers manufactured in the last several years and leads to otherwise working and good printers being wasted by being thrown out wasting its owner’s money and adding to the landfill problem.

With the cost of printers being what they are the hardware somewhat subsidised at the expense of consumables. This leads to end users who experience an error with their printer will likely go out and buy a new printer rather than have it serviced to clear a fault such as ink absorption pad full especially with lower cost ‘disposable’ consumer grade printers.

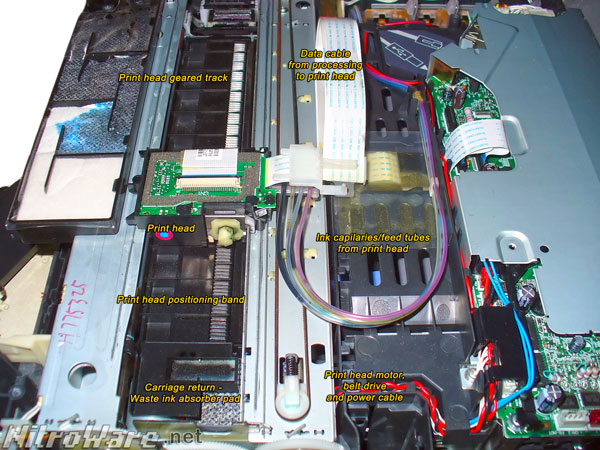

When an inkjet printer is turned on from a cold and off state it will go through a deep clean cycle to clear out any old and dried out ink from the printing head to ensure that no ‘gunk’ ends up on the users printed document. The way this is achieved is via the use of cleaning apparatus in the printer such as a rubber or plastic squeeze wiper to swipe the surface of the print head or metal pins.

This approach will clean the surface of the print head but will not clean out the microscopic nozzles in the print head. Thus forcing fresh ink through the print head will clear out any old ink and essentially ‘rinse’ the print head ready for quality printing. The printer will also perform a cleaning cycle based on a schedule or timer as well as printed page count.

The downside of doing this is that precious ink is ‘wasted’ during the cleaning operations. To prevent ink from being wasted try not to turn off your printer from the hard power switch or from the wall. This will only confuse the printer and waste ink through cleaning cycles. It is for this reason inkjet printers typically only have a standby switch on the front panel and may not have a hard power switch. When the printer is in its standby mode it is in a ready to print state and will not waste ink or performs unnecessary cleaning cycles in this state, preserving ink.

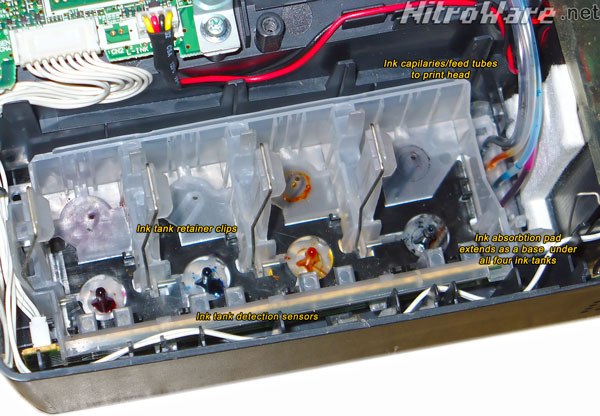

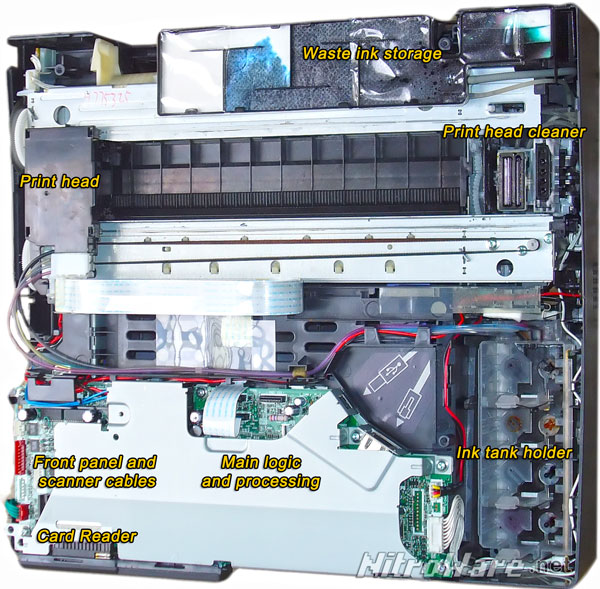

The actual implementation of the ink absorption/waste system varies. Some makes use a small pad directly under the home position of the print heads to collect waste ink. Some makes use an elaborate system of several pads/sponges under the print heads as well as a separate large tank containing a large sponge connected to the print head via plumbing to collect waste ink.

The manufactures design the capacity in such a way that the end user should get a significant amount of pages printed before the pads will fill up and the printer will indicate an error and stop printing. We cannot give an average page cycle as this is vendor specific.

Users who print on a light or casual basis who may turn off their printer after printing a small number of pages may reach this capacity limit of waste ink sooner as compared to a user who may keep their printer on standby there will be more cleaning cycles and wasted ink per actual printed page for the former than the latter.

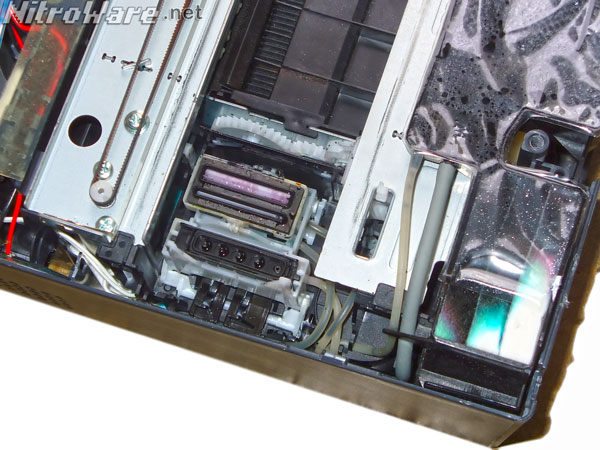

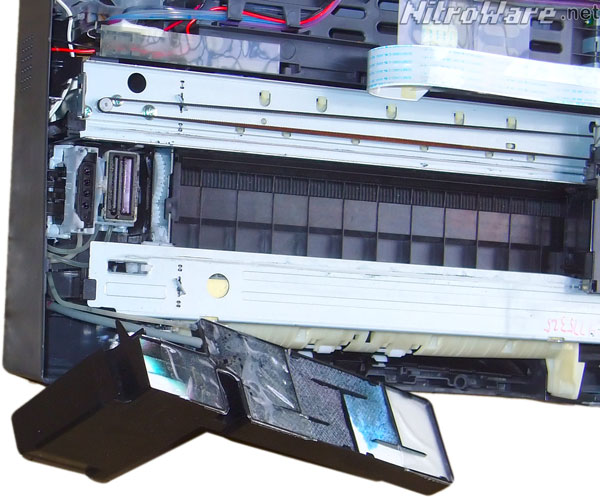

To illustrate our comments throughout this article we have dissected a Brother MFC-620CN multi-function inkjet printer to show the significance of the ink absorption pads.

Â

This particular printer we are using as a reference for this article would not print due to an error being indicated relating to the ink absorber being full, although the pipes that carry the waste ink could also be blocked leading to the same issue.

As you can see from the following photograph, the ink absorber pad in the printer is quite large, almost the width of the printer and that with the particular printer featured it is almost full.

Typically, these parts are not user serviceable and can/should only be replaced by an authorised service agent. Some enterprising end users choose to dismantle their printers and rinse out the ink pads on then own using a hose or other device. This is a very messy process and we do not recommend it nor is a result guaranteed. Not only can moisture or water get into the printer through the wet pad but the service manual is needed to correctly disassemble and reassemble the printer. User modification of their printer voids the warranty.

If the concept of ink being wasted or ‘going down the drain’ as we have coined, we have a few suggestions.

- Use a laser printer instead of an inkjet. There is less wastage with this technology

- Use a business or enterprise grade inkjet which will have bigger and more economical ink tanks and possibly user replaceable waste management.

- Deal with it. Waste ink is a consequence of using an inkjet printer and it is normal behaviour.